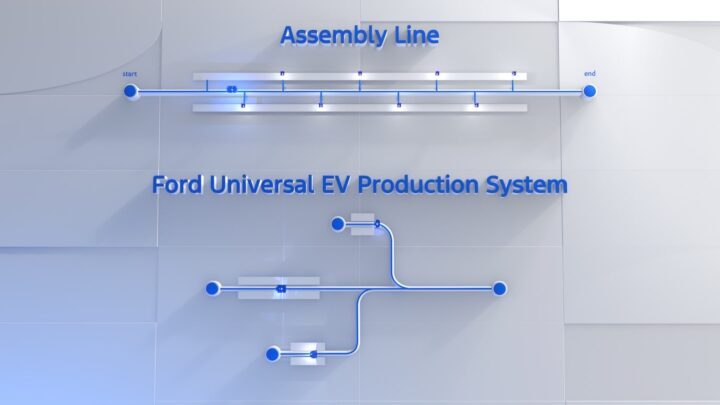

Ford is reimagining vehicle manufacturing with the debut of its universal EV production system, a cutting-edge process designed to enhance efficiency, reduce costs, and improve ergonomics for workers. This system will debut at the Louisville Assembly Plant, which is being retooled to build the automaker’s upcoming generation of affordable electric vehicles.

Unlike traditional conveyor-style assembly lines, Ford’s new system uses an “assembly tree” approach. Instead of one long production line, vehicles are built in three separate subassemblies: the front, the rear, and the battery pack with interior components. These are then brought together into a final assembly, streamlining the process while reducing complexity.

The innovation doesn’t stop there. Ford has also adopted large single-piece aluminum unicastings to replace dozens of smaller parts. This simplifies assembly, reduces the need for extra connectors and wiring, and improves product consistency. Workers benefit as well, with carefully organized tool kits and a design that minimizes bending and reaching – boosting both efficiency and safety.

The end result? Ford estimates the Louisville Assembly Plant could see production speeds up to 40 percent faster compared to older methods, with around a 15 percent net efficiency improvement after accounting for automation and insourcing. Beyond speed, this approach promises lower costs, higher quality, and a better experience for workers, positioning Ford as a leader in modern, scalable EV production.